More than 896+ Company Supported 164 M invested on core placements through Placementshala.

English | Hindi | Tamil | Malayalam | Telugu | Kannada | Marathi

Introduction to Electrical Wiring

Basic Electrical Circuits / Drawings

Relays

Circuit designing using Relays

Relay Wiring

Introduction to Industrial Automation

Automation Tools

PLC Architecture

Programming Languages

Ladder Diagram

Implementation on Logic Gates

Rules for Programming

Latching and Unlatching

Introduction – Automation

PLC Hardware/ Architecture

Relay/ Digital Logic

Ladder Logic Programming

Functional Block Programming

PLC scan cycle

Bit, byte and word instructions

Compare/Logical /Arithmetic

Program control instructions

Timer, Counter Configuration

Instruction set

Upload/Download /Monitoring of program

Forcing inputs & outputs

Analog input/ output addressing

Digital input/output addressing

PLC Troubleshooting

I/O Modules configuration

Sub routine & interrupts programming

Panel wiring

Communication drivers

HMI/ SCADA interface

Applications

Introduction – SCADA

Creating database

Images, objects configuration

Dynamic properties (blinking visibility, movement, filling )

Tag creation and addressing

Tag grouping

Macro editor

alarm/ events configuration

Trends – real time and historical

Database and DDE connectivity

I/O driver configuration

Interfacing with PLC

Wireless SCADA/GSM PLC, Recipe

Introduction

Drives

Drive systems

Internal circuits

VFD selection

Parameterization

Checking load

Rated voltage

Rated current

Rated RPM

Commissioning, No Load Test

Interfacing PLC to VFD

Speed Modulation

on/off command

Interfacing AB PLC with SCADA and HMI

Interfacing M221 PLC with SCADA and HMI

Interfacing Delta PLC with SCADA and HMI

Interfacing GE Fanuc PLC with SCADA and HMI

Interfacing Omron PLC with SCADA and HMI

Interfacing Mitsubishi PLC with SCADA and HMI

Introduction to AC Motors

Introduction to MCC Panel (Motor Control Centre)

Starting, Controlling and Protection of Motor

Starters – DOL Starter, Star – Delta Starter

MCC Panel Wiring

Plc wiring

Panel designing

Introduction to P & FI

Calibration

Transducer

Sensor

Basic Instrumentation Parameters & Variables

Temperature Measurement

Pressure Measurement

Case study

Plc programming

Scada designing and interfacing

Introduction – DCS

DCS Hardware/Architecture

I/O Module Configuration

Controller Configuration

Controller Module Configuration

Programming-DCS

Basic I/O

Logic Gates

Timer/Counter

Compare/Compute

SCADA

Basic Introduction

Digital/Analog

Animation

Trend/Alarm

Communication

Automation is one of the most simple and robust technologies in the world. Learning it takes a bit of effort, as knowledge in Automation needs to be polished from time to time with the latest updates. SMEClabs itself being an Automation company offers you all the latest advancements from time to time. An Automation Engineer is one who has skills not just in programming but also has remarkable skills in the following:

One should have skills to determine the exact I/O card configuration, power supply required, determination of safety measures etc. To be an Automation Engineer who can create wonders, one should work out various exercises and develop skill in Troubleshooting. The entire process starting from programming to interfacing should be done repeatedly. The study of PLCs would only cover 40% of technology that Automation is involved in. Automation is actually the study of Automation tools where one is taught programming, installation and troubleshooting of these tools. The major tools of Automation are as follows:

Another important point to be acknowledged is that, there are various brands that support Automation and as brands change the UI changes, Communication protocols change, Hardware configuration change, functionalities change, etc. Thus it is very important to be a master in the leading and most widely used brands in the market while the others remain a copy of these brands. Such top-class widely used brands are as given below:

So always keep in mind, to be a master Automation Engineer, it is very important to be focused and have knowledge that is self-gained, where one gets to repeatedly work with disassembly and assembly of Automation systems starting from programming to successful installation and testing.

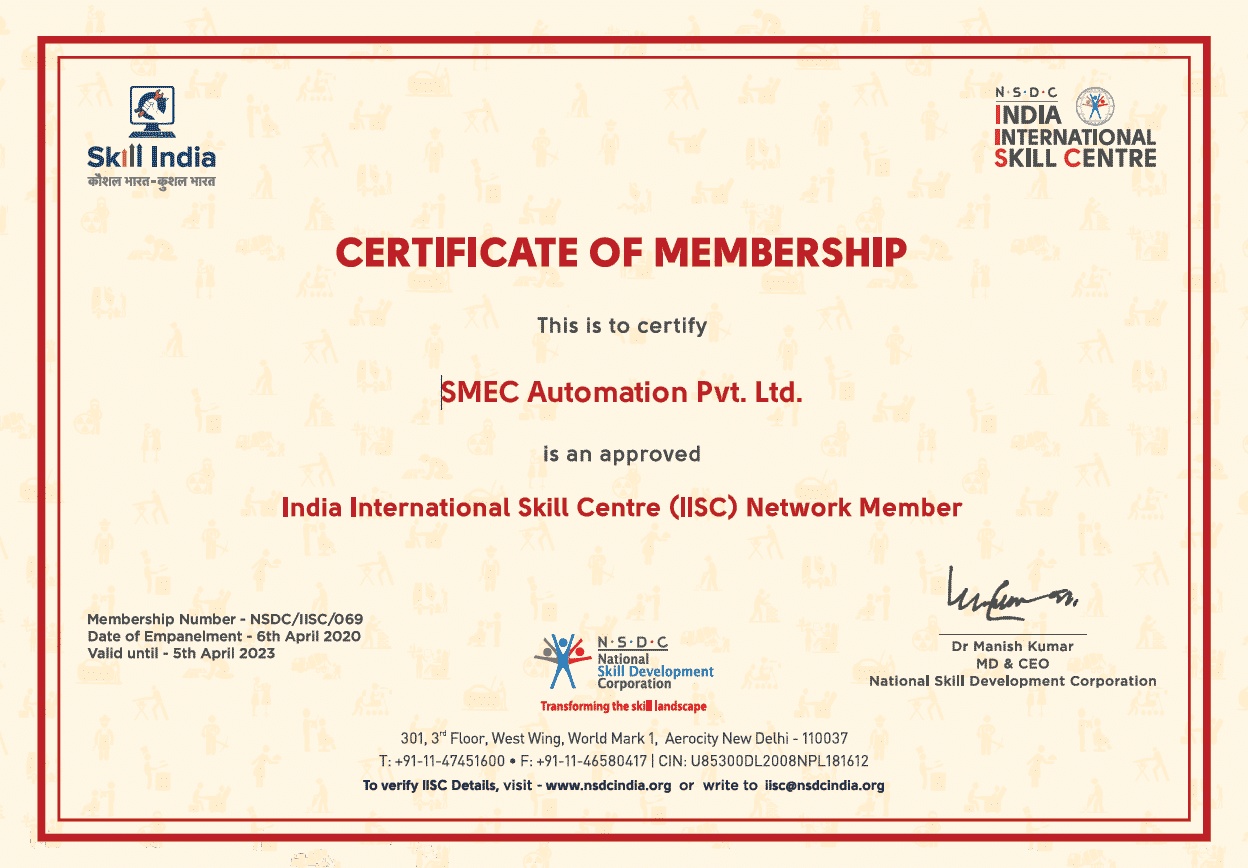

SMEClabs offers complete master-level training. Delivering, the one of its kind Hybrid Training that would give you all facilities of practical training while learning from home. SMEClabs will give you kits and working models of projects, using which you can learn every module in detail. Complete assistance in a trained lead skill enhancement program. SMEClabs will also give you global certification for various levels of training.

2nd Floor Kaloor Bus stand Complex Cochin. Ph: +919958873874, +919656227714

1317 Edgewater Dr #2874, Orlando FL 32804 Ph: +14077680955

30 Cecil Street,#19-08 Prudential Tower

Singapore – 04971